Product philosophy

Our manufacturing process

Nova Sidera handles the order from beginning to end.

The careful selection of raw materials and detailed production of components, reinforced by our selective group of reliable suppliers and strong global presence, form the foundation on which our machinery and services are built. Internally, Nova Sidera handles the order from beginning to end, starting with the initial design, followed by processing and finishing with machine tools, up to the final assembly, programming and testing of its products, culminating in outstanding technical assistance and user/refresh training for our spinning lathes.

Customized formulation and design

From drawing to drafting machine to 3D modeling.

Each project starts by providing a customer solution that satisfies regulations and measurement systems from around the world.

The engineering department is the linchpin of the system, supporting sales using both standard models as well as completely new and innovative solutions. Our strength lies in flexibility and customization. Our work has a dual nature—while industrialized and technological, it is also very artisan.

The technical aspect is characterized by the components and software chosen for the construction of machinery, which are constantly in the forefront in terms of both production and organizational processes following Transition Plan 4.0 guidelines.

The craftsmanship aspect, however, allows flexibility and provides the opportunity for customization of products and services based on the actual needs and requests of the customer.

This approach also extends to research and product innovation initiatives, which are constantly keeping pace with actual production needs in order to anticipate market demands. In this context, successful collaboration among customers and suppliers is crucial in order to create an endless, stimulating drive for new ideas and insights.

From raw material to finished product

Nova Sidera has always produced exclusively to specification while applying lean manufacturing principles and has developed, over the years, its own organizational and production system consistent with Transition Plan 4.0 guidelines. Every phase of the order’s life cycle is overseen with management software, and the production process is organized by production orders and company Manufacturing Execution System (MES) for control and progress monitoring throughout each production phase.

The process also includes a connection with the management software of the sawing machine, work center, and milling cutter for production control and remote programming via Computer-Aided Drafting (CAM), as well as the automated warehouse.

Each material and component is coded and located in two different warehouses, depending on type. Raw materials are stored separately in the machining department while purchased components, semi-finished products and finished products are stored in the vertical automated warehouse with 32 drawers and a total of 115 m2 of useful surface area.

Nova Sidera has been investing in its own machining department since 2018. This investment is motivated by Nova Sidera’s belief that quality is not just what you see in the finished machine but also represented by every single component and process used to produce it.

Where a lathe is born for Nova Sidera

At least 80% of machining operations are carried out in-house specifically for the vital parts of the machine, while the processing of electro-welded components and any heat or surface treatments are contracted out to qualified suppliers. Thanks to the use of a 5-axis DMG work center, we can process machine components of up to 2 meters in length. Both this work center and the other CN cutter available on site can be programmed quickly and precisely using the latest-generation CAM.

This approach allows us to specifically train our staff, especially those involved in testing and after-sales service. Technicians can learn the details of each production phase of the machinery, greatly reducing response times and facilitating the troubleshooting of each structural unit of our spinning lathes while gaining a deeper understanding of the reasons behind the technical choices made.

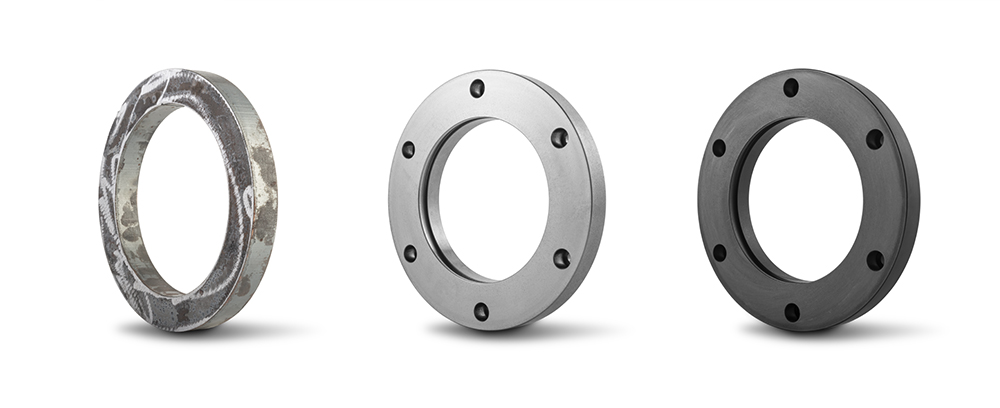

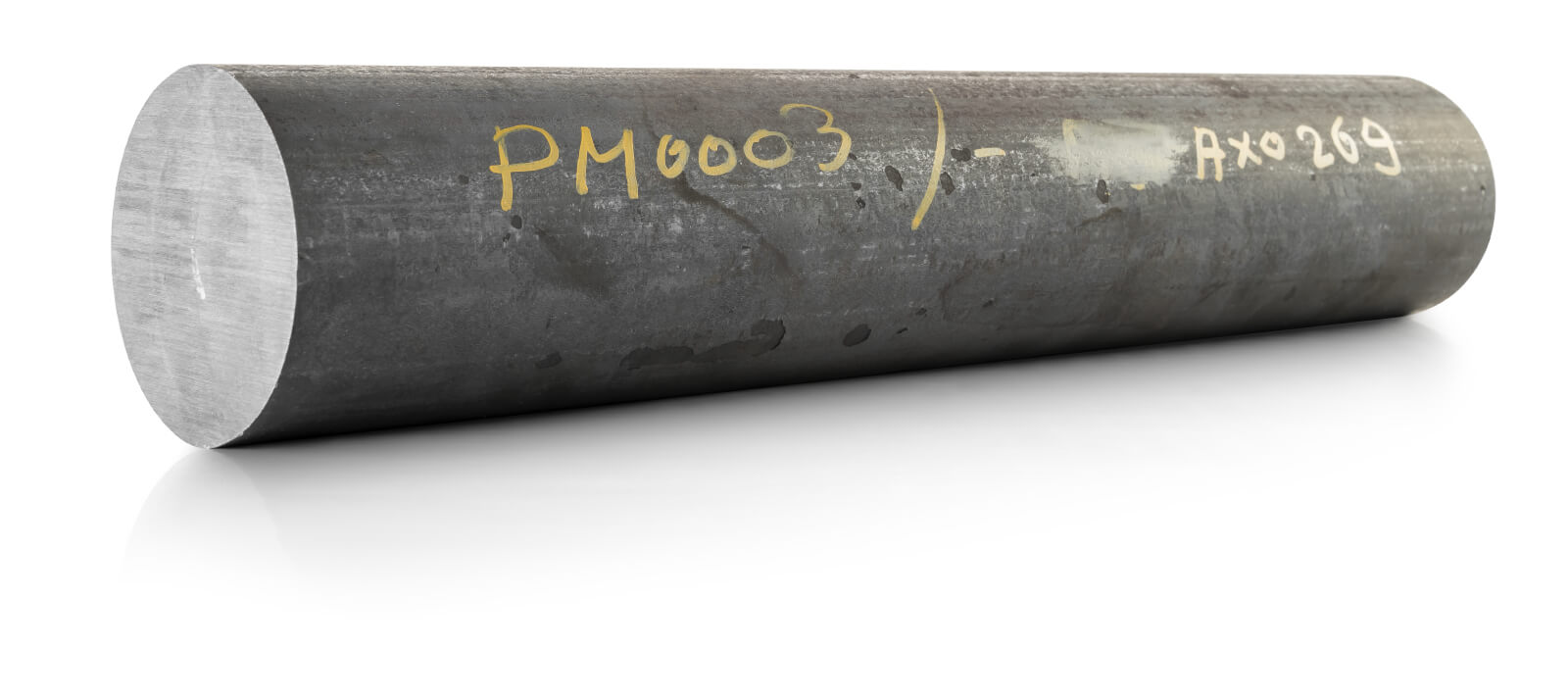

The difference is in the raw material.

Every machine starts with the most precise and meticulous choice of material depending on its intended use, as the quality of the material determines the service life of the components and reliability of the spinning lathe itself.

From hardened steels to super rapid steels, alloy steels and even aerospace aluminum alloys and carbon alloys, Nova Sidera capitalizes on specific material characteristics to improve and optimize the performance of its machines.

The machining department comprises the following areas:

- Welding area

- Raw material cutting area with automatic sawing machine and Nova Sidera circle cutters

- Removal turning area with CN lathe and manual lathes

- Milling area with a 5-axis DMG work center (Model DMF260) and DEBER CN milling cutter (refurbished by Nova Sidera)

- Adjusting area with column drills, grinder

Other processing

Proper alignment is essential in order to fully harness the machine’s power. The primary assembly phase of our spinning lathes is alignment of the components. The mechanical department performs the alignment following precise procedures with the aid of a 2-meter measuring arm and precision mechanical instruments guaranteeing tolerances of up to 0.02 mm.

The machine assembly tolerances are recorded in a report to be analyzed and subsequently filed with the job order.

Taste is subjective, quality is not.

We measure quality.

Technical filing.

Archiving the technical file of each individual order is another essential step in facilitating the efficiency and effectiveness of the service department. A unique job order number is associated with each machine. This number is registered in the company management software and matched with the buyer, indicating the specific machine equipment in order to guarantee both documentary and technical traceability of the individual product. In the event an issue arises, this traceability allows for quick and proper identification of the broken or defective component and ensures its replacement with minimal machine downtime. Moreover, it is also important to have record of the state of the art at the time of any retrofit, verification of compatibility with accessories requested and installed later, or the creation of compatibility kits for older machines.

The appeal of machining.

Accuracy and exactness in the machining of precision mechanical parts, in addition to quality and reliability, lead to enhanced aesthetics of the machinery.

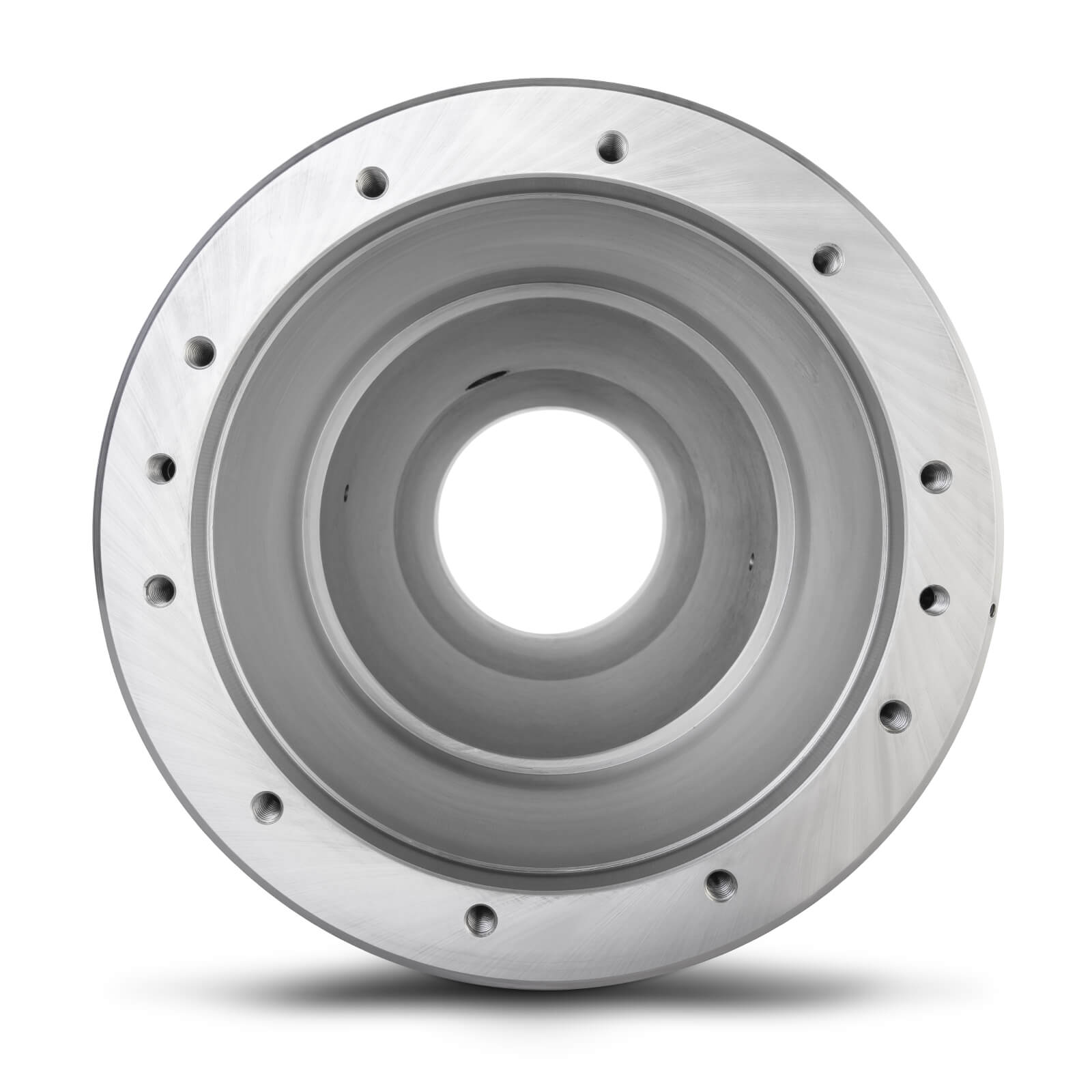

Thanks to precise milling and grinding with 0.01-mm tolerances, our spindle supports are the foothold of the entire machine structure for both sheet spinning and even machining of the molds, finished directly in the spinning lathe. This provides a significant advantage as it creates the tool directly in the machine, making it practically perfect for production with the chosen machinery.

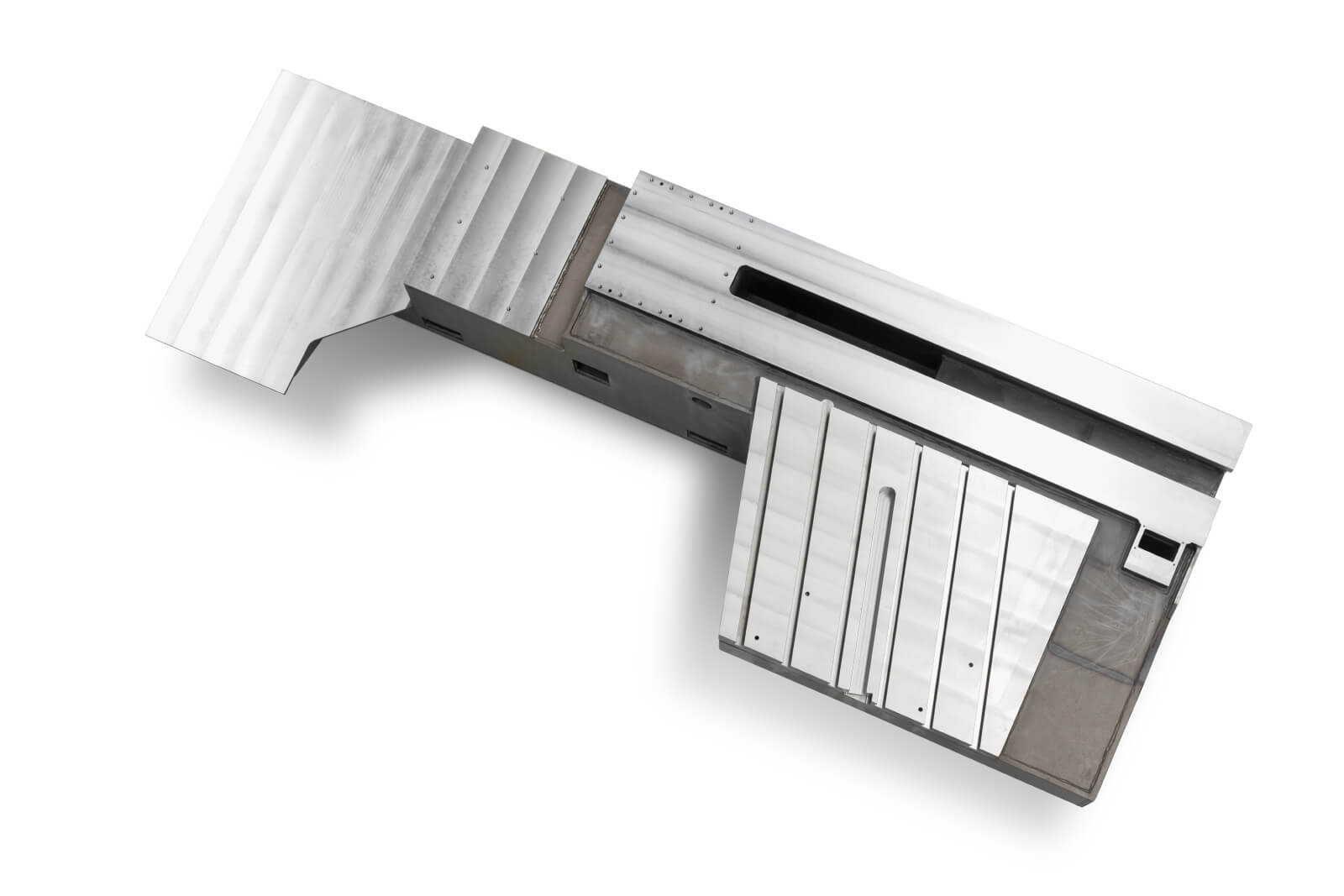

It all starts with solid bases

Our bases will never be too small and light or too big and heavy. They will only be properly sized. Steel is a precious asset and should be used correctly at the right points, with proportions commensurate with the actual size of the machine.

Each base consists of a normalized electro-welded steel structure with, depending on the model, internal passages or arrangements of struts and folders designed to allow proper passage of electric cables and hydraulic hoses.

Base tailstock and headstock: the importance of alignment

The assembly mechanic uses an internal procedure, with the aid of specific measuring instruments such as the measuring arm, to perform a pre-alignment of the individual unfinished components for verification of nominal dimensions before painting. Later, during assembly of the units, the center of the spindle axis is aligned with the center of the tailstock axis with a maximum tolerance of 3-4 hundredths.

In the lathes with the Nova Sidera Easy Spinning playback system, the layout of the machine is the same as that used since 1990. The machine is structured with two opposite operating areas. One part is identified by the playback joystick where the first piece is programmed while the other is the operational part for loading and unloading the pieces during production. This machine configuration allows the operator complete visibility of the work area during any self-learning programming, without the roller and mold obstructing the view, thereby benefiting from hand-eye coordination while programming the part being spun.

Spindle and turret: the winning combination

Sheet spinning deforms a metal disk or blank, transforming it into a drawn piece shaped by the mold previously mounted on the spindle. Both the spindle and turret are actively involved in the deformation process through their proper sizing and configuration.

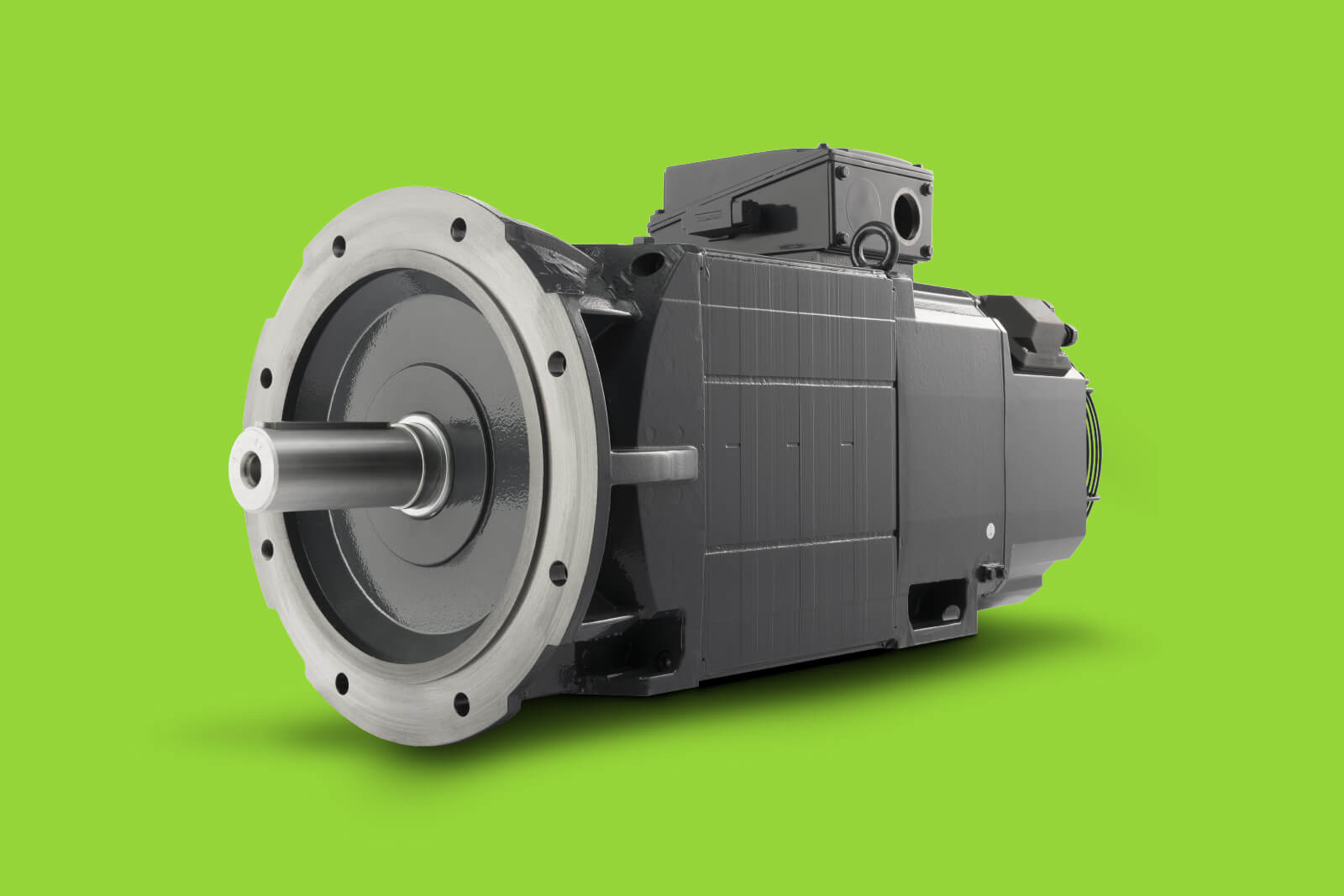

Spindle.

The spindle supports the flange that anchors the mold. The mold replicates the desired finished shape, rotating at different speeds during the progressive deformation of the sheet metal. The spindle is located in the headstock opposite the tailstock.

Made of Fe430 steel, it encompasses high design standards through the Finite Element Method (FEM) to meet both technical and ergonomic needs.

Turret.

The turret is the component on which the material deformation rollers, trimming rollers and trim accessories are mounted. Depending on the spinning lathe model, the number of tool seats and their layout (horizontal or vertical), as well as the constructive configuration (with toolbar pass or not, fixed or with tool holder backing pad), can vary. Tool turrets allow for more demanding processing with rapid and precise tool changes.

The iteration between spindle and turret, spindle RPM, and the speed of roller passages all play an important role in the successful production of precise, high-quality lathe-turned parts. Their respective positioning provides for effortless servicing and maintenance by facilitating operator access.

Focused on energy savings since 1990

Our machines are able to work quickly and precisely, while at the same time saving energy, thanks to the specific characteristics of our parts.

Our spindles house high-energy-efficiency motors and regenerative drives in network. The network regeneration allows for the production of energy during braking, thereby reducing the overall energy consumption of the production process.

Plug and play wherever you are.

The spindle design allows for worldwide availability of spare parts and complete disassembly of the entire unit for revision. The spindle unit is designed to be “plug and play” (except for the Eureka, Vega 800/1000 and Zeus models). The customer can remove the whole spindle unit independently and send it to our service department for repair. The customer will receive the entire repaired unit ready for independent assembly on the machinery.

This approach significantly reduces machine downtime and simplifies repairs worldwide.

Just the right balance between standardization and craftsmanship.

All our spindles have a standard DIN 55027 connector, and each machine model has its own spindle size (ASA) which will be the same worldwide. This allows for interchangeability of flanges among different spinning lathe models and even different brands.

Expulsion of the piece.

Depending on the requested application, all our models can be accompanied by an ejector and/or vacuum. The expulsion of the piece can therefore be pneumatic, hydraulic or a combination of the two.

The extraction stroke varies depending on the machine model on which it is installed.

The electrical panel, a true nerve center

Built internally by design, the electrical panel is the brain of our machines. It contains components from leading international manufacturers to deliver reliable performance over time and guarantee the availability of spare parts, even after many years of service, ensuring continuity in the service life of the machine.

Even the electrical cabinet, the push-button panel arm and the entire electrical system are assembled internally by Nova Sidera. Over 2,500 meters of individually numbered and signed electrical cables make troubleshooting simple, even remotely.

Aesthetics and so much substance.

The electrical system and cabinet have been connected to Siemens numerical controls since 1990 and FANUC numerical controls since 2019. Depending on the model, the interface is full touch screen or industrial with a QWERTY keyboard.

The choice to assemble numerical controls produced exclusively by leading suppliers, rather than industrial PCs or dedicated software, guarantees easy access to service worldwide, regardless of the machine manufacturer. It also allows the customer to have a spinning lathe with machining capabilities and greater flexibility in the event of interpolation of multiple axes simultaneously using robot or Cartesian interlocking.

Artful packaging

Choosing the best packaging and transport with well-established carriers guarantees optimal arrival of your spinning lathe. Our machines travel by land (on rail or road), sea and air. Depending on the delivery method, the packaging will consist of a protective bag with drying salts, fumigated wood pallet or crate and container. Packaging instructions and anchoring photos travel with the machine to facilitate handling operations and unloading upon arrival at destination.

Courtesy package

The investment in a new production tool is always exciting but also a source of concern for the customer, as it undoubtedly requires the internal reorganization of both company processes and dedicated staff.

We believe it is critical to work side by side with our customers to provide support and make the new project as stress-free as possible.

In addition to the product line of spinning lathes and special sheet-forming machines, Nova Sidera also offers a complete range of services to its customers worldwide. All models, with the exception of the larger Vega and Zeus models, are designed to travel fully assembled for quick on-site commissioning at the customer’s factory.

After sale

Our work does not end with the production of the machine; production is actually just the beginning of a long and rewarding relationship with our customers. We support our customers with on-site and remote technical service, training and updating courses, and consulting.

The year 2020 has demonstrated how important remote support is when there is little to no opportunity for travel, but it has also shown us how the proper use of well-known and widely available technology can save time and resources. Nova Sidera has been keenly aware of these tools since the early 1990s.