Vega

Spinning Lathes

Vega 800

With a deformation capacity of up to 10 mm of R40 steel disk with diameters of up to 1640 mm, Vega 800 represents one of Nova Sidera’s top models.

The unique layout with enclosure guarantees the highest safety standards and optimal ergonomics for machine tooling.

Three models

Nova Sidera unit

Steel R40

Stainless Steel R70

Some data

Energy used

Power

Precision

| Features | Unit | 600 | 800 | 1000 |

|---|---|---|---|---|

| Height of centers | mm / inch | 650 / 25.29 | 820 / 32.28 | 1.050 / 41.34 |

| Distance between centres | mm / inch | 1.200 / 47.24 | 2.000 / 78.74 | 2.500 / 98.42 |

| Max disc diameter | mm / inch | 1.300 / 51.18 | 1.640 / 64.57 | 2.100 / 82.67 |

| Deformation capacity | Unit | 600 | 800 | 1000 |

|---|---|---|---|---|

| Aluminum | mm / inch / Gauge | 15 / 0.59 / 000000 | 15 / 0.59 / 000000 | 15 / 0.59 / 000000 |

| Steel R40 | mm / inch / Gauge | 10 / 0.393 / 000 | 10 / 0.393 / 000 | 10 / 0.393 / 000 |

| Stainless steel R70 | mm / inch / Gauge | 6 / 0.263 / 3 | 6 / 0.263 / 3 | 6 / 0.263 / 3 |

Each model can be customised and all other data will be provided according to the customer's actual needs.

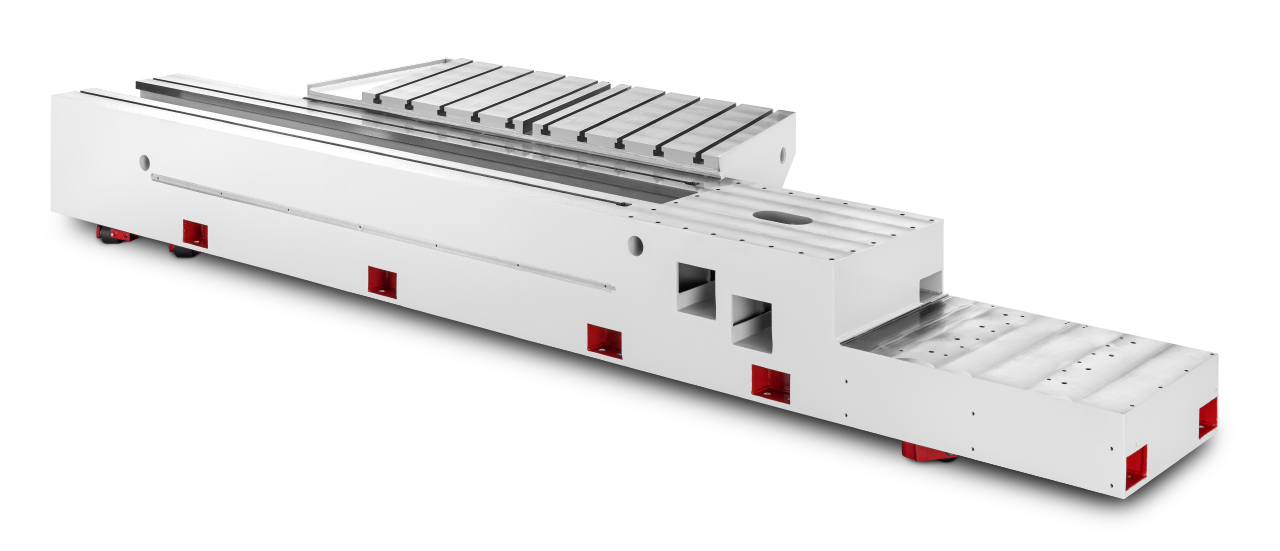

It all starts with solid bases

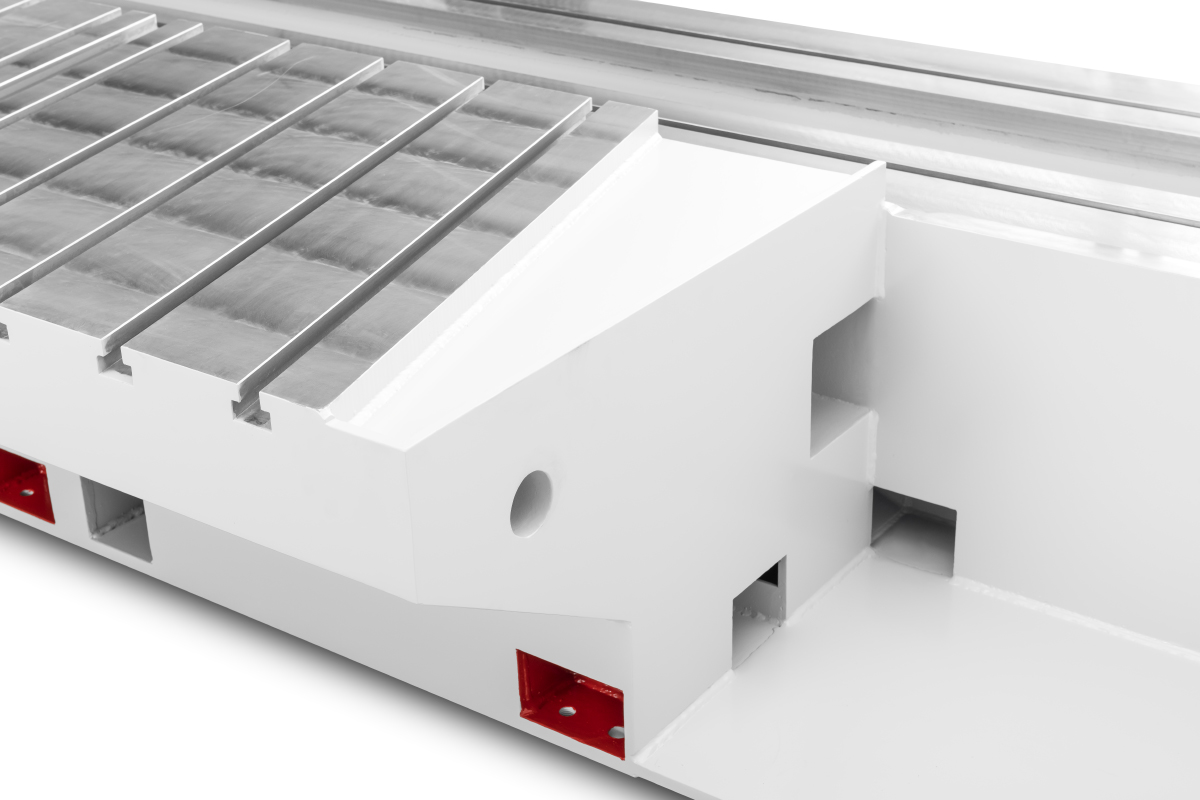

Our bases will never be too small and light or too big and heavy. They will only be properly sized. Steel is a precious asset and should be used correctly at the right points, with proportions commensurate with the actual size of the machine.

Each base consists of a normalized electro-welded steel structure with, depending on the model, internal passages or arrangements of struts and folders designed to allow proper passage of electric cables and hydraulic hoses.

The bases are designed to facilitate handling of the entire machine by providing special seats for the passage and anchoring of slings when using self-propelled cranes or gantry cranes. The lifting holes are placed strategically so that once the spinning lathe is assembled, the center of the triangle or quadrilateral of holes corresponds to the center of gravity of the machine.

The turned and burnished leveling feet are easy to adjust during commissioning to anchor the base to the ground and provide simple alignment of the machinery.

To allow for quick and easy start-up, our bases do not need to be secured to the ground. Depending on the machine model, the base can be sitting on the ground or designed to be inserted into special holes in industrial warehouses, allowing easier operator access to the work area for more powerful lathes with larger diameters.

The processing quality of the upper surface of the base is essential to allow proper alignment between the main axis group, headstock and tailstock of the entire machinery as well as their movement and repositioning when processing requires a larger inclination of the roller with respect to the disk.

Our focus is on

The careful selection of raw materials and detailed production of components, reinforced by our selective group of reliable suppliers and strong global presence, form the foundation on which our machinery and services are built. Internally, Nova Sidera handles the order from beginning to end, starting with the initial design, followed by processing and finishing with machine tools, up to the final assembly, programming and testing of its products, culminating in outstanding technical assistance and user/refresh training for our spinning lathes.